Call Us

+86-15017908688

Website

www.synspeed.com

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Synspeed Smart Conveyor Systme can build Smart SMT Line. This is a solution that enables an enterprise-wide integrated management and automated production line.

The AOI Island is proving to be popular, with multiple customers using the setup to replace reliance on a dedicated operator. Typical payback is only a little more than a year compared to a system requiring an operator and, at this time when recruitment and retention of staff is proving to be so di

Synspeed releases the latest generation of inline laser marker machine for electronics manufacturing

The Hermes Standard (IPC-HERMES-9852) provides the state of the art for board flow management along mixed vendor lines in SMT assembly.

Views: 0 Author: Site Editor Publish Time: 2023-10-07 Origin: Site

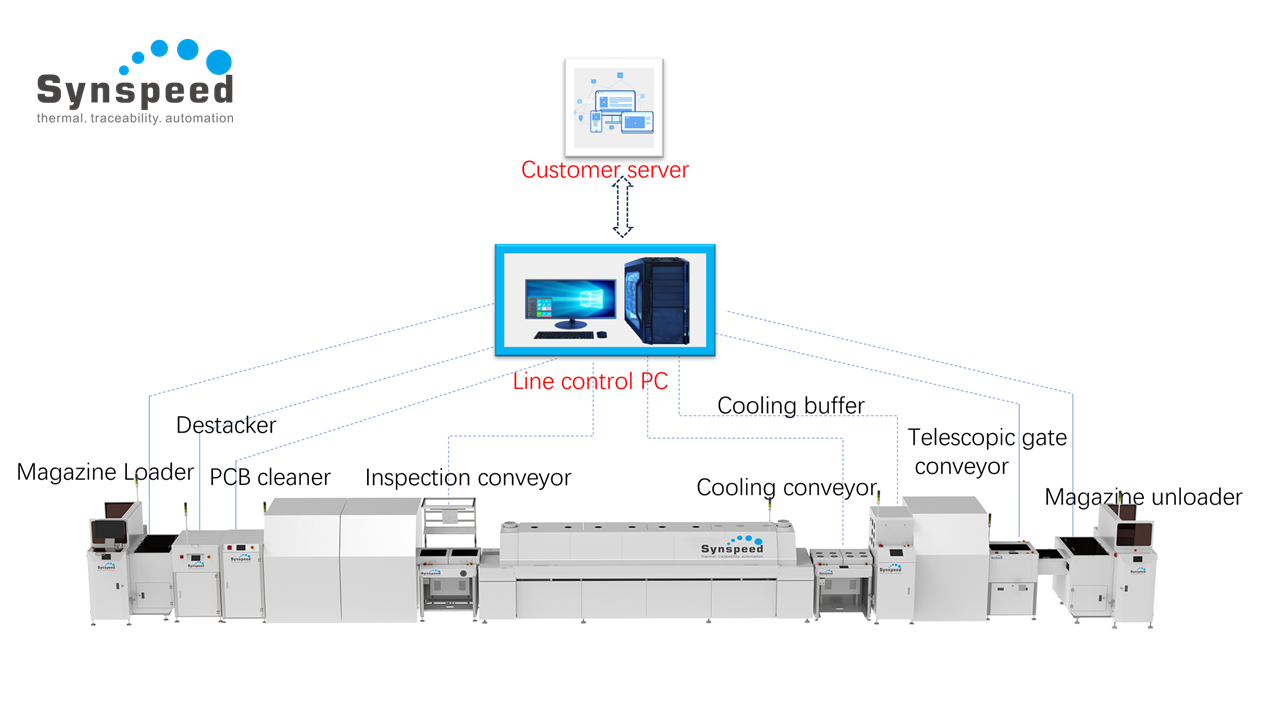

Synspeed Smart Conveyor Systme can build Smart SMT Line. This is a solution that enables an enterprise-wide integrated management and automated production line.The Synspeed equipment constituting the smart SMT line is connected to the line control PC(A separate computer for central control of the Synspeed facilities) through LAN communication. The customer transfers the PCB information to each Synspeed facility through the line control PC, so that the operator can change the width easily. In addition, it is attracting attention as a next-generation SMT solution that improves the productivity and competitiveness of customers by enabling real-time monitoring of facility status.

The optional features :

Interface between the Line Control PC and Customer’s server– The Customer SERVER reads the result value of each transport device of Synspeed’s stored in Line Control PC.

In case of NG Buffer or Unloader, it is possible to trace the board of a specific slot during production– Serial # required, the factory’s main server has to be connected

Conveyor speed can be set by model– The machine must be equipped with an electronic speed control controller in advance.Ex) Cooling Link in front of/ at rear of reflow oven

1) Automatic width adjustment | When applying the data of the production model, each transport device of Synspeed carries out automatic width control. |

2) Real-time status monitoring | Real-time monitoring possible with PC |

3) Maintenance Alarm Function (Optional) | If the maintenance period is set to a certain cycle for each equipment, an alarm will ring. |

4) LogFile Creation | Production history management and infinite data processing |

5) Set access permisiions | The user can edit accessibility to the system |